|

|||||||||||||||||||||||||||||||||||||||||||||||||||||

| Manual or Robotics | |||||||||||||||||||||||||||||||||||||||||||||||||||||

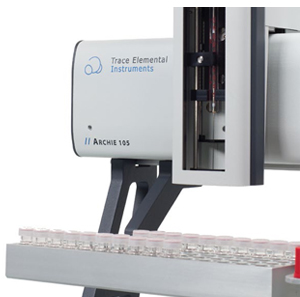

| There is still a choice as to how you'd like to run your samples. 24/7 or just a couple of samples a day. For manual liquids there is an integrated automatic syringe driver. It offers full control over the desired volume and speed of injection. For manual solids introduction, there is an integrated software controlled boat drive. Both features do come standard with every Xplorer. If the choice is full automation, a robotic XYZ autosampler, ARCHIE-105, handles all liquids. The ARCHIE-105 allows direct injection either by boat or vaporizer. For LPG's and Gas there is a revolutionary, fully automated sampler, GLS. It can run as a stand-alone, method driven, gas sampler, using a touch screen as user interface. Connected to the powerful TEIS software it simply runs in slave mode to the XPLORER. Just run your sample list and the liquefied gas or gas sampling is in full control. Automatic handling of solid samples can be executed by the NEWTON 20 autosampler. It handles sample cups for various applications. No matter what choice you make: every bench marking design feature, enhances the overall quality, saves time and significantly reduces the need for spare parts. |

|||||||||||||||||||||||||||||||||||||||||||||||||||||

| Compliance and Regulations | |||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||

| Xplorer System Specification | ||

| Dimensions (W x H x D) | 40 x 28 x 70cm (15.7 x 11 x 27.6 inch) | |

| Weight | 34kg (74,8Ibs) | |

| Voltage | 100-240 V, 50-60 Hz | |

| Power requirement (max) | 1150 W | |

| Gas connector | 1/8" Swagelok | |

| Gases | Oxygen 99.6 % (2.6), Argon 99.998 % (4.8) | |

| Input gas pressure | 3-10 bar | |

| Internal gas pressure | 1.8 bar, adjustable | |

| Furnace voltage | Dual zone, low voltage | |

| Furnace temp. (max) | 1150 °C (2102 °F) | |

| Furnace cooling | Pulling Fan, auto control | |

| Sample introduction: | tlqulds direct injection, Solids by boat, Gas by GLS module | |

| Sample size: | Solids: 5-1000mg; Liquids: 100 uL; Gas: 10 mL; LPG: 100 uL; | |

| Semi-automatice boat/syringe driver: | Software controlled, adjustable method file | |

| Slider/shutter driver | Software controlled, adjustable | |

| Detector Sulphur | Xenon Pulsed UV-fluorescence AFC technology | |

| Detector Nitrogen | Chemiluminescence | |

| Detector accuracy | Better than 2% CV | |

| Detector conditioning | Temperature controlled, adjustable | |

| Vacuum pump | Internal 24 Volt DC | |

| Software | dot. NET-based, TEIS software | |

| Ambient temperature | 5-35 °C (41-95 °F) non condensing |